- Details

The evolution that has distinguished rotational moulding in recent decades is intimately related to the development of awareness of rotomoulding in the design world. In other words, as the potential of rotomoulding becomes “common

The evolution that has distinguished rotational moulding in recent decades is intimately related to the development of awareness of rotomoulding in the design world. In other words, as the potential of rotomoulding becomes “common

knowledge” amongst designers and producers the sophistication of their projects using our technology for industrial applications grows. RotoTrends explores the different potentials of rotational moulding showing case-histories where the roto technology is able to open new markets, developing innovative products and working successfully in new niches.

The projects developed in partnership with international design institutes, and the selected industrial products produced a faithful portrait of an industry constantly hungry for new ideas, eager to experiment with new shapes and new materials, sensitive to the international richness of globalization.

- Details

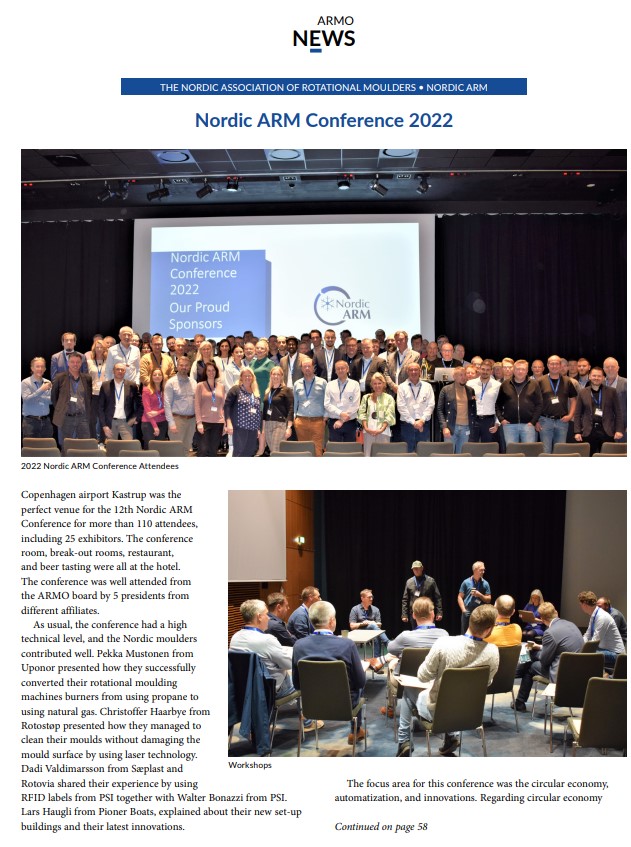

The 12-th Nordic ARM Conference 2022 took place in Copenhagen on the 11th and 12th of October.Participation of over 110 rotomoulding professionals from Scandinavia and other countries, high-level presentations, excellent workshops, involving table tops and the famous Nordic ARM quiz allowed Ronny Ervik, the Nordic ARM Chairman and the Nordic ARM Board members to create the unforgettable conference.

The 12-th Nordic ARM Conference 2022 took place in Copenhagen on the 11th and 12th of October.Participation of over 110 rotomoulding professionals from Scandinavia and other countries, high-level presentations, excellent workshops, involving table tops and the famous Nordic ARM quiz allowed Ronny Ervik, the Nordic ARM Chairman and the Nordic ARM Board members to create the unforgettable conference.

Thank you everyone for participation and making the Nordic ARM event succesful. Please see below the ARMO News conference report and the photo gallery:

nordicarm - Nordic Arm Events

We look forward to meeting you all at the next conference planned in Iceland in 2024.

- Details

Dear All,

The Nordic ARM Conference for 2022 is on. A bit delayed we will arrange the biyearly Nordic ARM Conference 11th and 12th of October at Clarion Hotel Copenhagen Airport. The conference was originally scheduled to take place in Iceland, but due to short planning notice we made the decision to postpone Iceland to 2024. Invitations will be sent out shortly. The Conference will focus on sustainability, innovation and automation.

We would like to receive presentation proposals as soon as possible. Some of the presentations are already confirmed:

-Using gas burner and still manage CO2 reduction

-Cleaning tools after machine breakdown. Learning the hard way

-New recycled materials for RM

-ABC of recycling for Rotomoulding

Looking forward to meet you all again.

Please do not hesitate to contact us if you have any questions.

Ronny Ervik

Nordic ARM Chairman and Conference Coordinator

- Details

The Affiliation of Rotational Moulding Organisations (ARMO) was established to provide an equal forum for organisations serving the global rotational moulding industry.

ARMO is in the process of creating problem solving application the rotational moulding industry. The app will be made available to all the ARMO Affiliate Members to discuss problems experienced in industry. Sponsorship opportunities will exist at a later stage for promotions etc. but will have a defined start and end date. The cost of the Sponsorship for Founder Sponsors will be €1 200. Should you require any additional information or to secure Sponsorship please contact us at This email address is being protected from spambots. You need JavaScript enabled to view it. Click on link https://xd.adobe.com/view/f27e5413-1f96-4633- a31d-a963d2a18616-a72d/ for a better understanding on how the App will work (after Development Phase1).

- Details

The first ARMO webinar, which is entitled 'Rotational Moulding Masterclass', will take place at 12.00 - 13.00 UK time on Tuesday 30 March.

The event will feature two speakers and is based on the recent AFR session. This event is exclusively available only to ARMO member companies and is free to attend.

This online event will provide attendees with a valuable insight into two important rotational moulding subjects:

* Efficient Demoulding

* 'Expand your horizons:- New moulding technologies, New materials, New Future'

Please see below the program details:

12.00 - 12.30 Efficient Demoulding In this presentation, Oliver Wandres, General Manager and Co-owner of Maus will present on the introduction of certain technical features or systems that will assist and help demoulding, as well as demonstrating with some case studies, how part design and mould layout can integrate demoulding concepts

12.30 - 13.00 ‘Expand your horizons:- New moulding technologies, New materials, New Future’ In this presentation, Matteo Cortesi, Sales Manager at Persico Spa will present on what the future holds for our industry, exploring new technologies and materials that will impact your organisation.

You can find more details and book your place at https://attendee.gotowebinar.com/register/4411971139323074571

Nordic ARM, Ekornveien 5, 3960 Stathelle, NOR

Nordic ARM, Ekornveien 5, 3960 Stathelle, NOR